It is possible to weld steel belts from a remote and safe location and to see immediately the weld beam being created. Service technicians are able to manoeuvre the TIG torch by using a joy stick on a remote panel and a flat screen display. The tungsten, welding wire and weld set-up can be exposed, magnified 20 times. The actual welding process can also be recorded and saved for safety or quality reasons. The camera system can be attached to any IPCO welding unit.

The remote controlled welding system comprises:

- 2-shaft linear unit with motors

- Tracking system

- Camera system – “Hornung”

- Flat screen

- Remote control unit

- Electronics

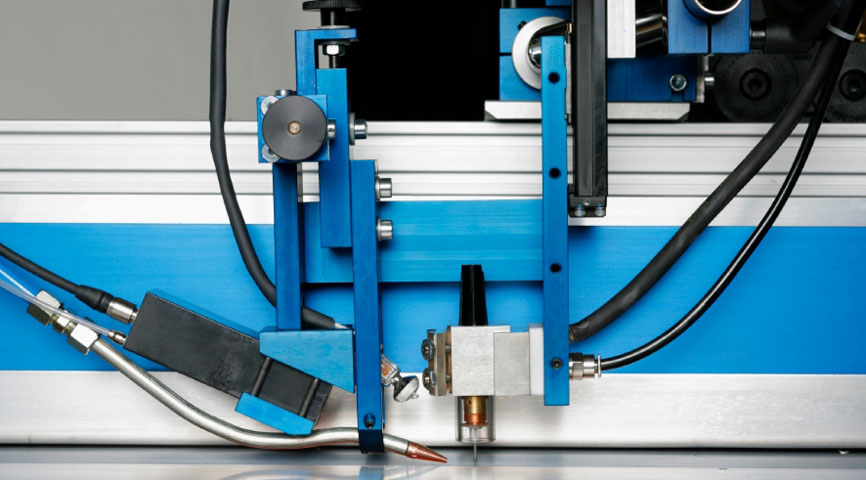

The welding unit is also equipped with the new, removable TIG torch head for automatic welding. The key advantages are easy removal from the welding unit and efficient adjustment of the tungsten set-up.