Digital Printing

Steel belts and advanced tracking technology working together to bring new levels of stability and productivity to high speed, high precision digital printing.

Businesses like yours across the digital printing industry are under pressure to increase productivity, create additional capacity or simply meet ever tighter deadlines through faster print speeds. But speed on its own isn’t enough – your print lines must also be able to deliver ultra-precise rendering, and that’s a real challenge with traditional plastic belts, which can vibrate on the press.

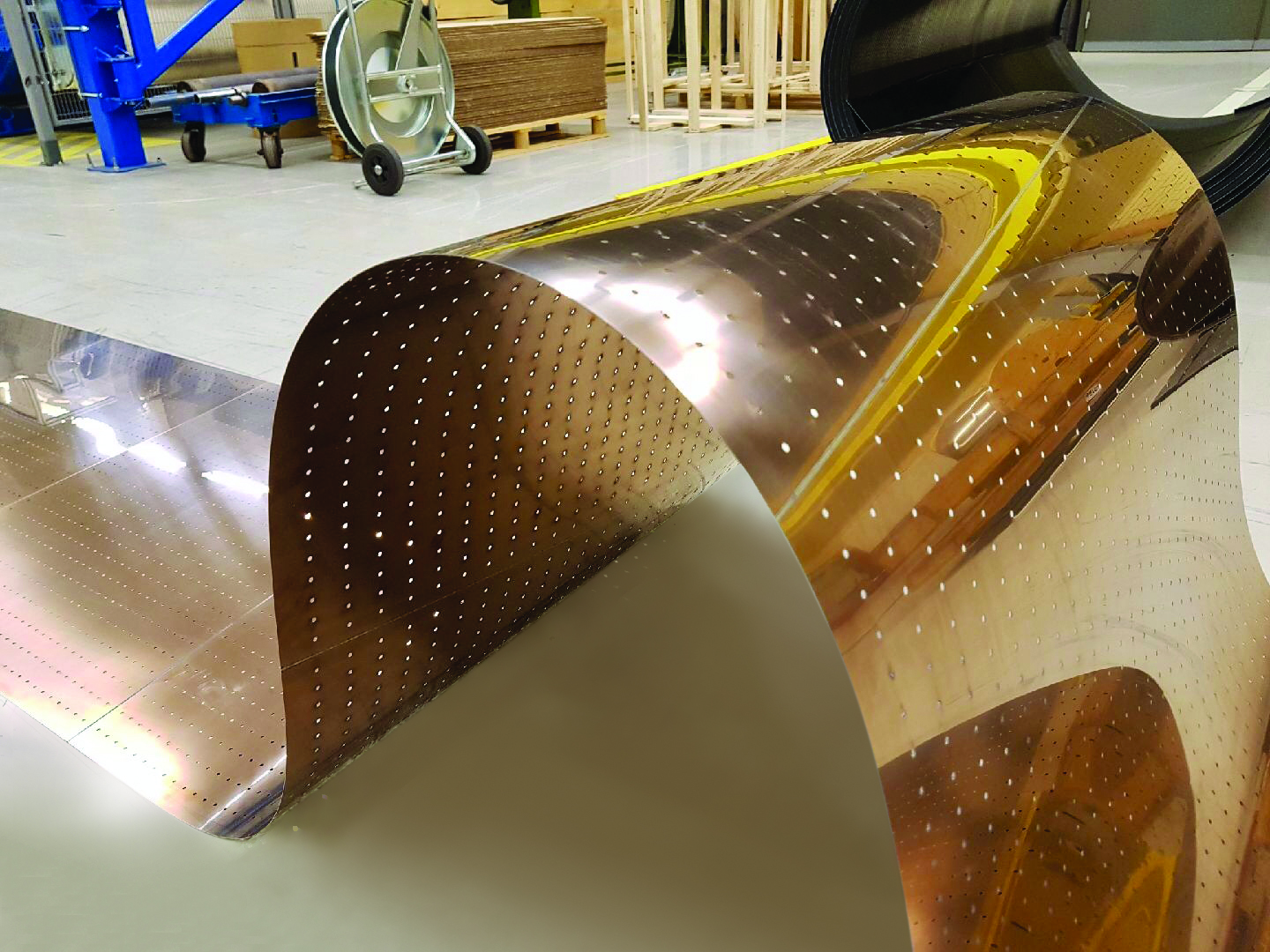

Steel belts

Steel belts are inherently flatter, straighter and more stable that plastic, which means you can run them at higher speeds while maintaining high precision ink placement.

This stability has been proven in independent tests carried out by contract research company Fraunhofer Institute for Production Technology IPT. Laser-based sensors were used to measure the vibration in steel and plastic belts at speeds from 30-300 m/min. Vibration levels were 3 to 6x lower on the steel belt, depending on speed and tension levels.

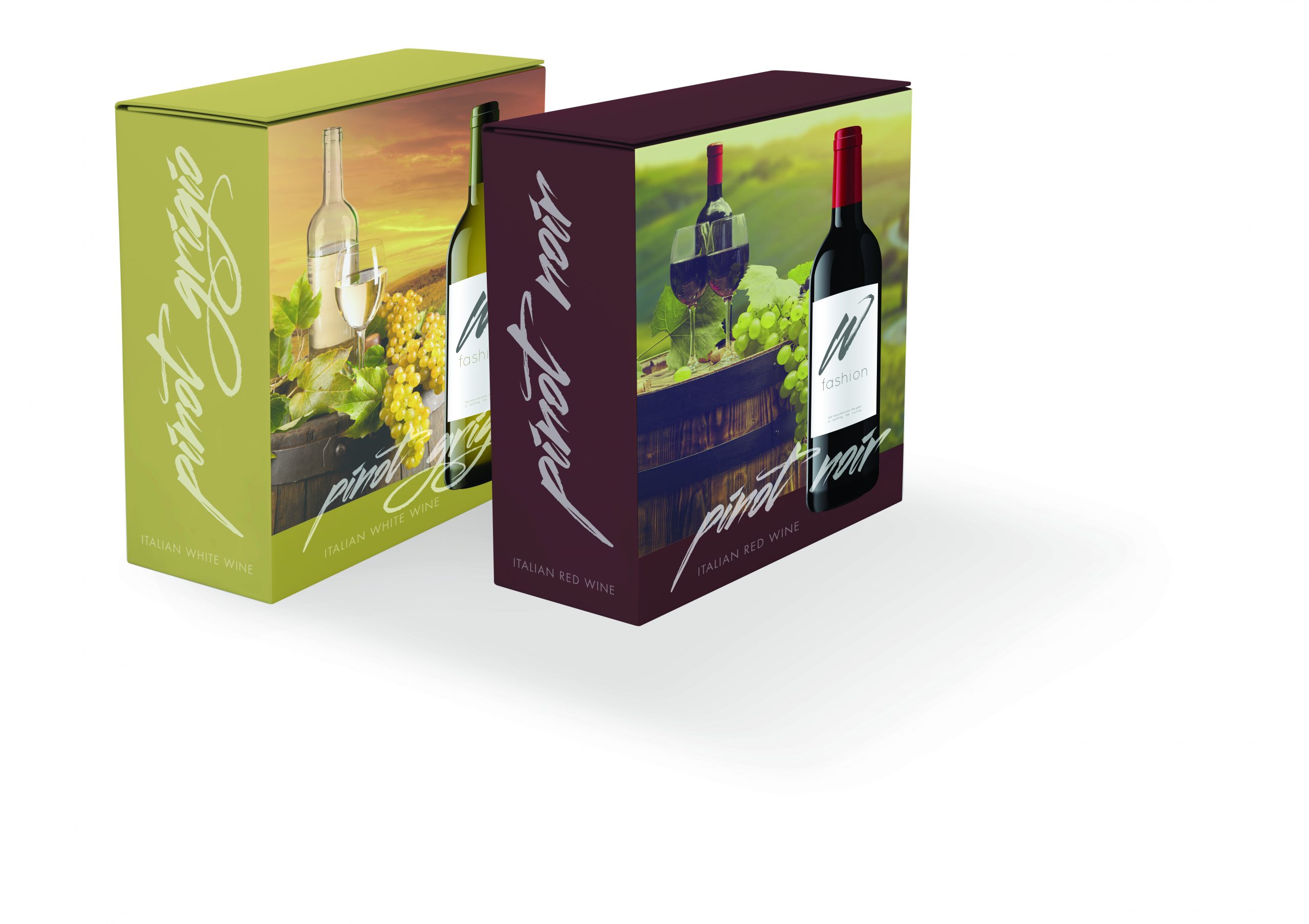

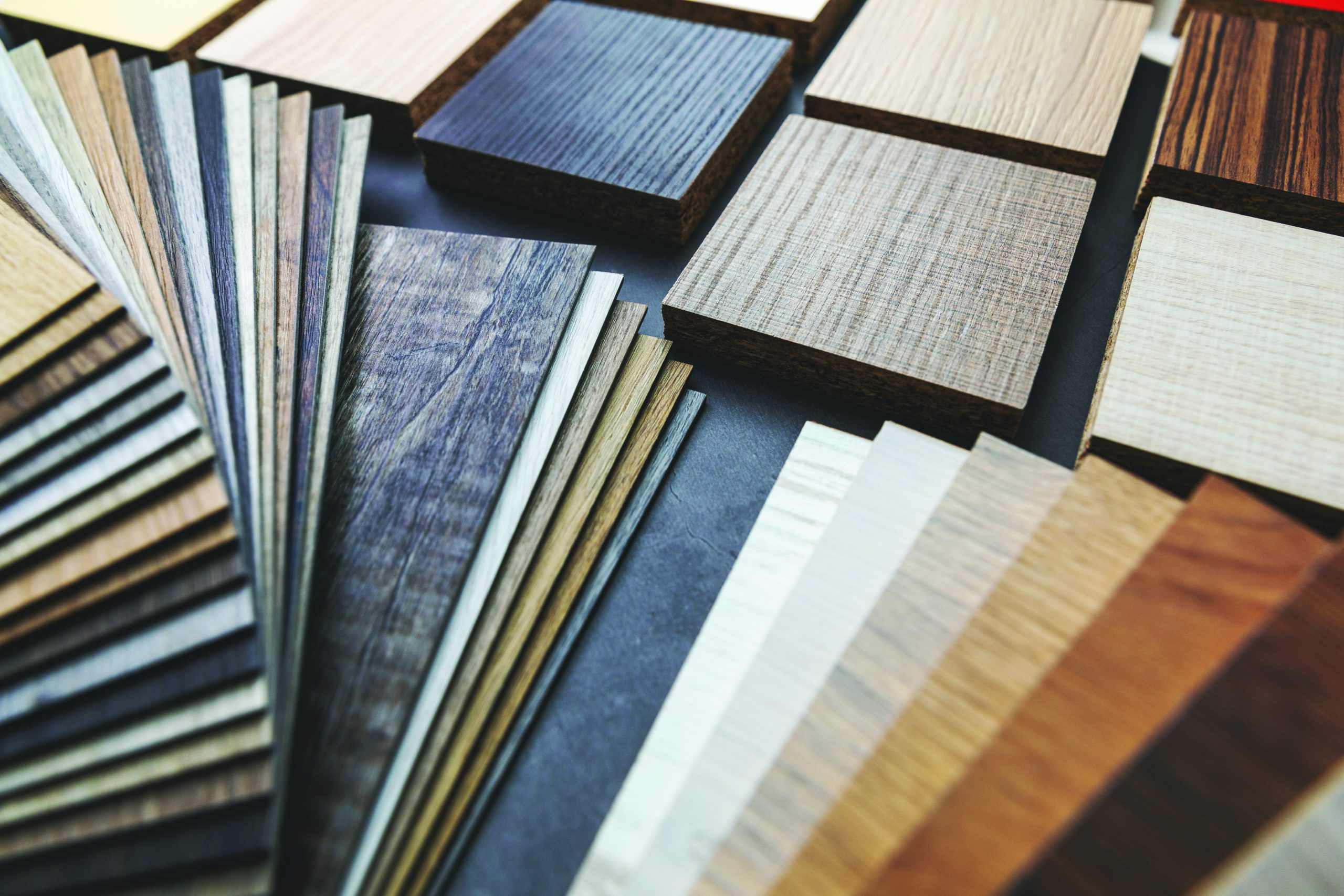

Applications for steel belts in digital printing range from large format corrugated packaging to high quality, full colour branded materials – even furniture board, film wrap and ceramic tiles.

High speed

- Higher belt speed, for greater productivity.

High precision

- Greater precision, due to virtually vibration free operation.

More productive

- Less downtime, thanks to the easy-clean properties of stainless steel.

IPCO service

High Precision Tracking

- Our High Precision Tracking (HPT) system offers fast, accurate belt tracking to within +/- 0.1 mm. Find out about our wide ranges of tracking solutions and other conveyor components here.

Solutions in numbers

Stability

6

Steel belts are up to 6x more stable than plastic

Pecision

<0.01

Belt tracking accuracy to <0.01 mm.

Speed

25

High speed tracking at up to 25 m/s.

Downloads

- Steel belts for high speed precision digital printing

- Vibration analysis of steel belts in digital printing