Innovative Cooling and Flaking Systems for Powder Coating Production

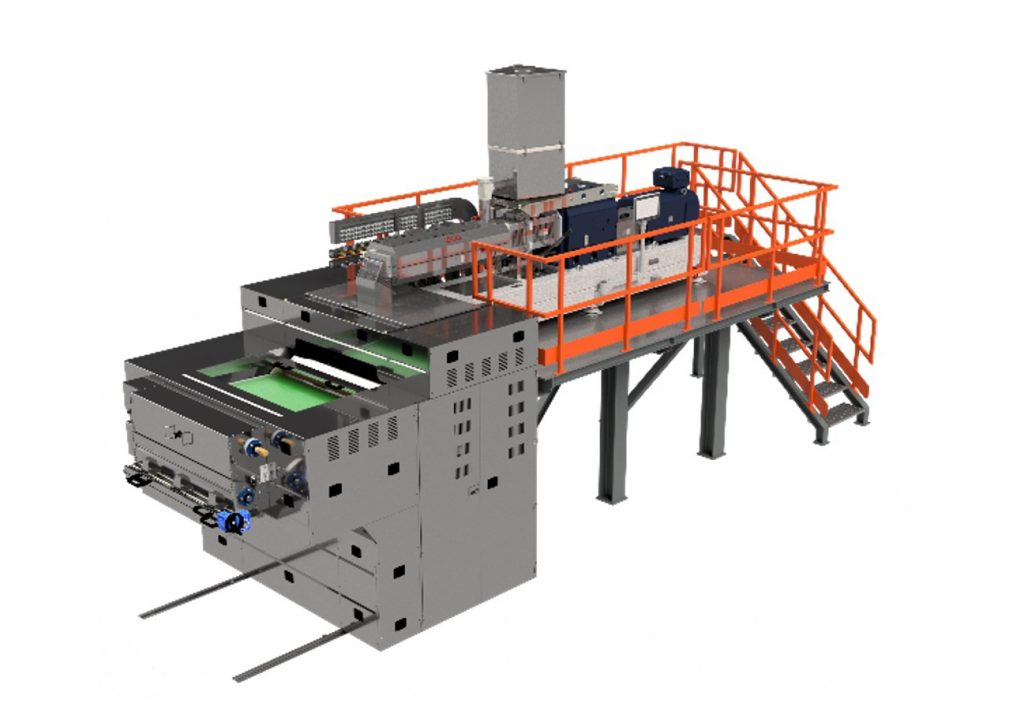

Explore our versatile cooling and flaking systems, engineered for efficiency in powder coating production. IPCO offers two distinct types of systems tailored to meet your production needs: our robust steel belt-based cooling conveyors and our dynamic plastic belt chill rolls.

Steel Belt-Based Cooling Conveyors: With throughput capacities ranging from 250 to 2,000 kg/h, these conveyors deliver significant advantages in durability and ease of cleaning. Ideal for thermoset powder paint production, the steel belt ensures cooling and flaking to the perfect size and thickness, optimizing the material for micronizing into powder coating powders.

Plastic Belt Chill Rolls: Capable of handling 60 to 1,300 kg/h, these chill rolls feature a multipolymeric composite belt designed for more compact system installations. This is particularly beneficial where space is at a premium or when fast-curing products are processed, as cooling takes place on the steel drum, not the belt.

No matter your specific needs, IPCO is here to support you with a complete processing system tailored to your powder coating production requirements. For more detailed information about our powder coating production equipment, click here or reach out to us using the form below.