Chocolate Processing

As a chocolate processor/manufacturer, you need equipment that will deliver the best balance of cost and productivity. Whether you’re looking for a high capacity system capable of maximising capacity from the available floor space for your chocolate lines, or a low-cost start-up solution, we have the system to match.

Trusted supplier since the 1930s

We have been a trusted supplier to the chocolate processing industry since the 1930s, when we supplied the world’s first cooling belt for chocolate drops to a customer in the USA. Today, we produce one of the world’s most comprehensive ranges of chocolate cooling and forming systems, and we have the process expertise to design the right solution for your particular chocolate manufacturing requirements.

Talk to us about your chocolate processing requirements, and we’ll deliver a solution that satisfies your objectives in terms of everything from budget and product type to throughput capacity and product quality.

Chocolate forming equipment for industrial products and decorative ingredients to

Our company has been built on innovative design and practical know how, and the IPCO name is recognised throughout the industry for reliable, high performance chocolate cooling and solidification systems.

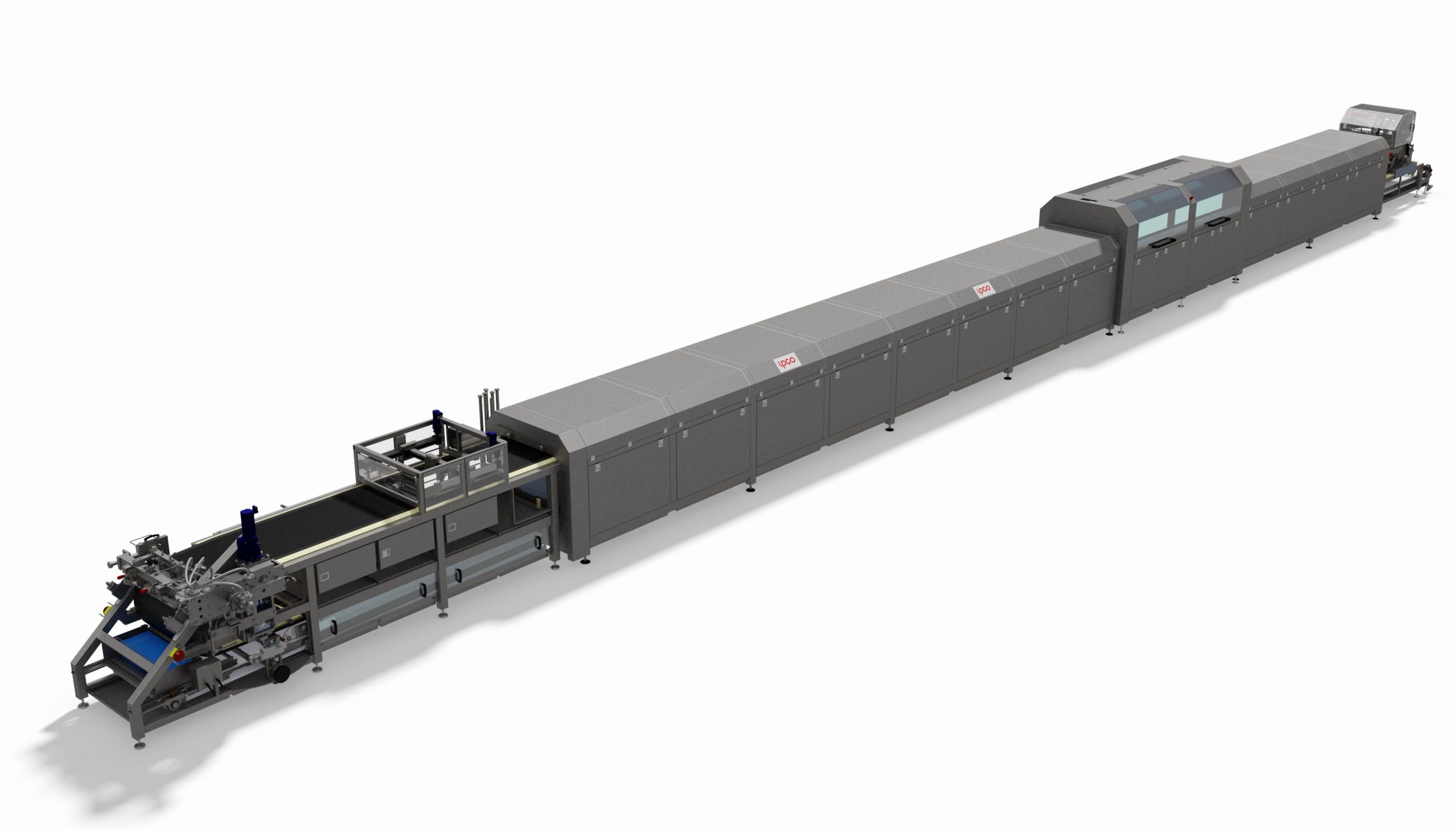

Chocolate lines

Whatever your requirement in terms of the form, size and output rate of your industrial chocolate products, we can supply an end-to-end forming system that will deliver the performance, quality and reliability you’re looking for.

Industrial chocolate products

Whatever your requirement in terms of the form, size and output rate of your industrial chocolate products, we can supply an end-to-end forming system that will deliver the performance, quality and reliability you’re looking for.

- Chips

- Drops

- Chunks

- Blocks

Decorative chocolate products

Our experience in the design and manufacture of chocolate cooling and forming systems means we can meet your precise requirement in terms of budget, capacity and quality. We have systems for the efficient versatile of decorative chocolate products including:

- Blossom

- Grids

- Pencils

- Plaquettes

- Rolls / sticks (single or duo-colour)

- Shavings

- Vermicelli

Chips/drops and Chunks are not decorative products but a decorative line is able to produce them as well.

System solutions for all throughput rates and floor space constraint

Our innovative approach to process design means we can combine and adapt our production components to deliver a tailored solution, one that gives you just what you need.

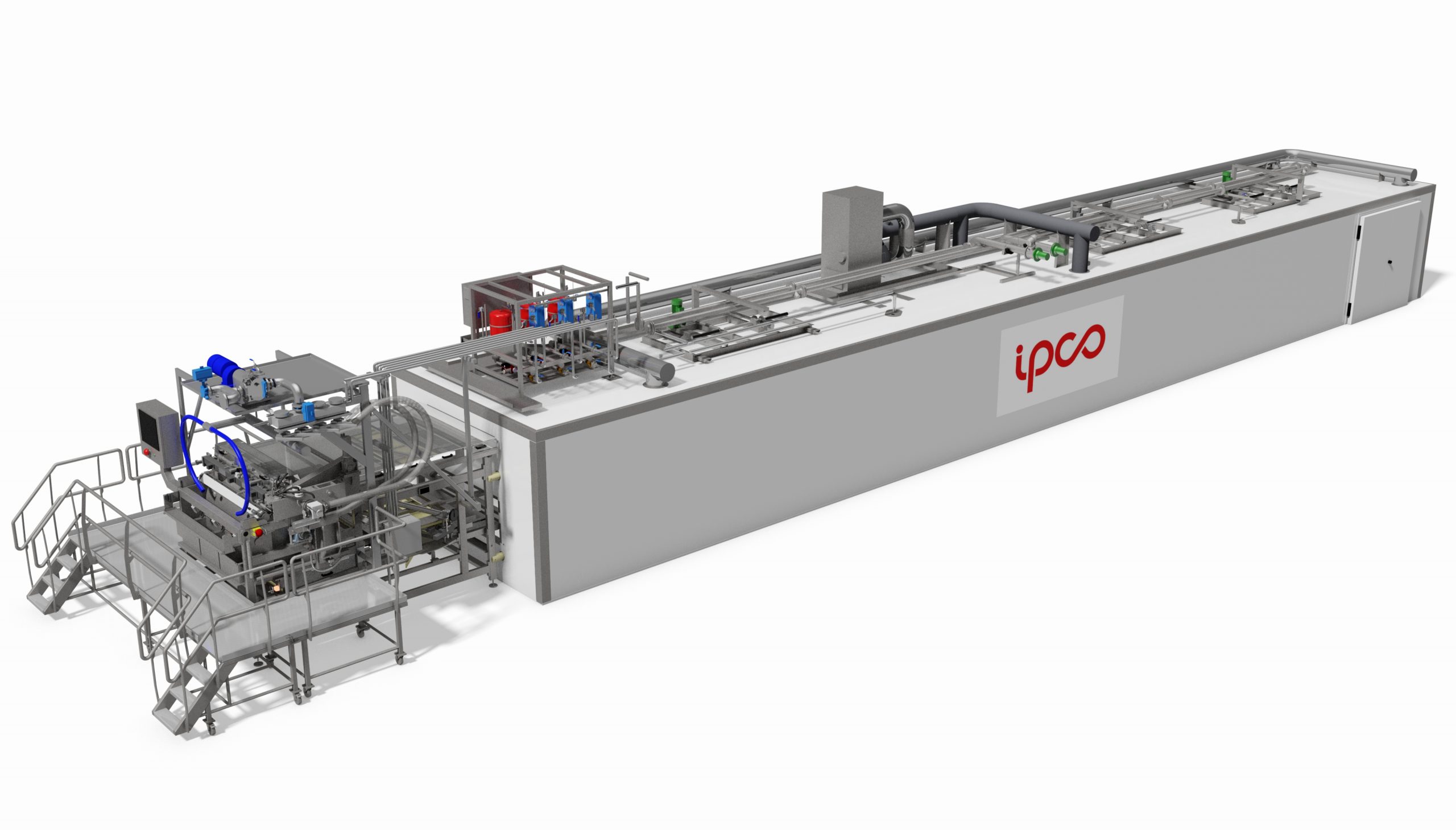

Tripple pass cooling

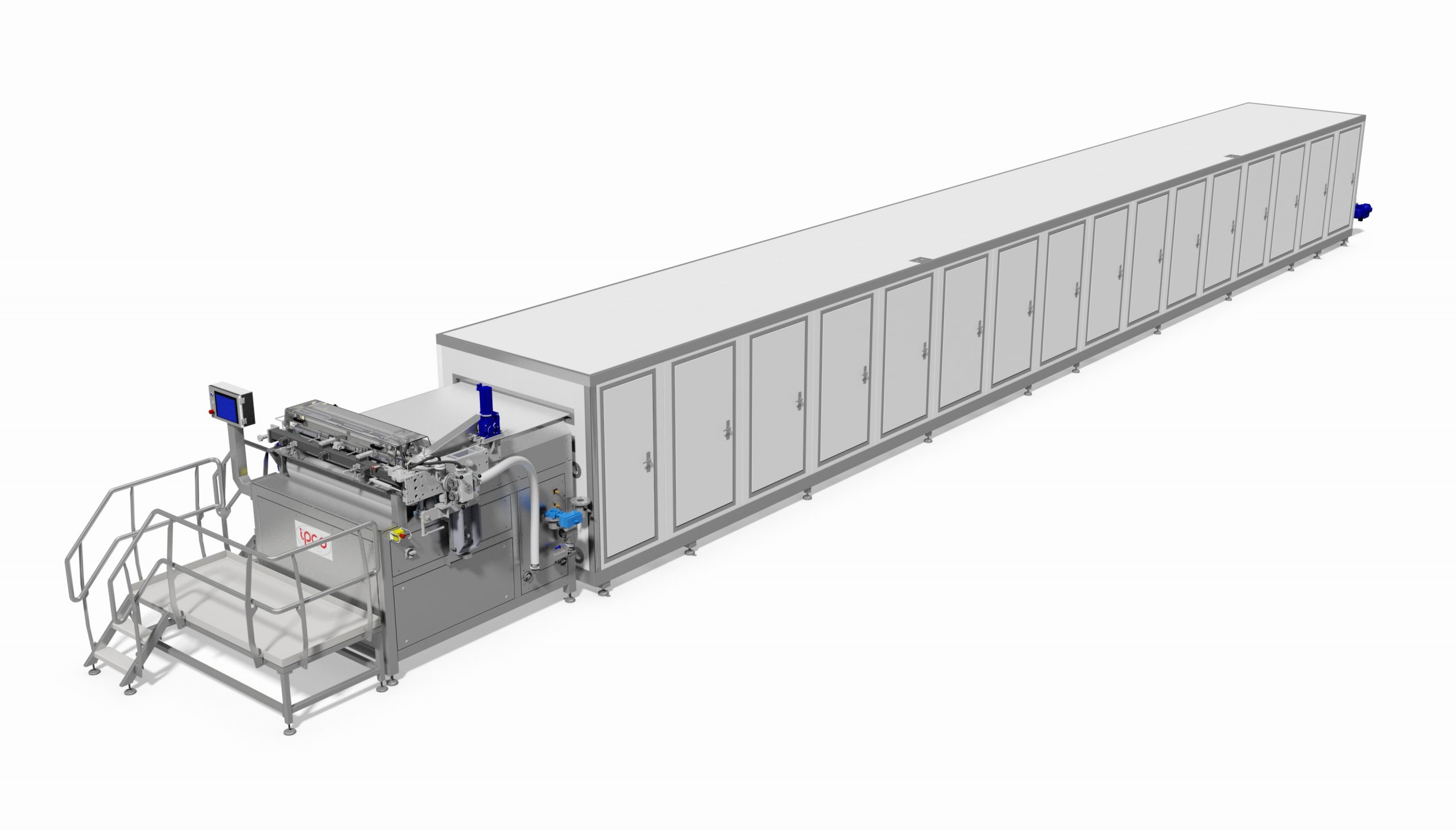

If you’re looking for low-to-medium capacity solution (e.g. 200-2,000 kg/hr), our single pass cooling lines offer an affordable choice. These systems can incorporate a gear or rotary depositor for chip production and/or extruder and servo cutter for chunks.

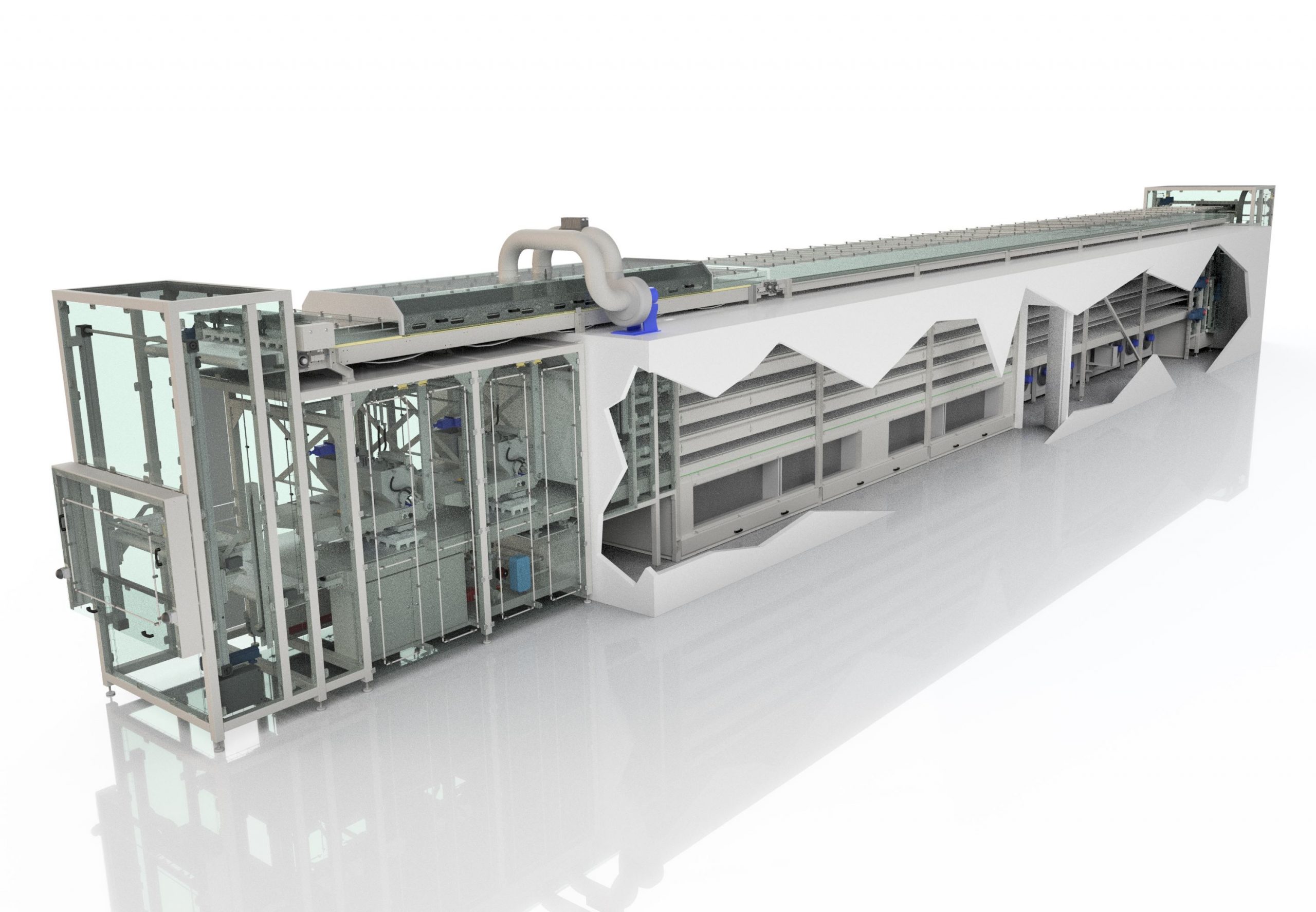

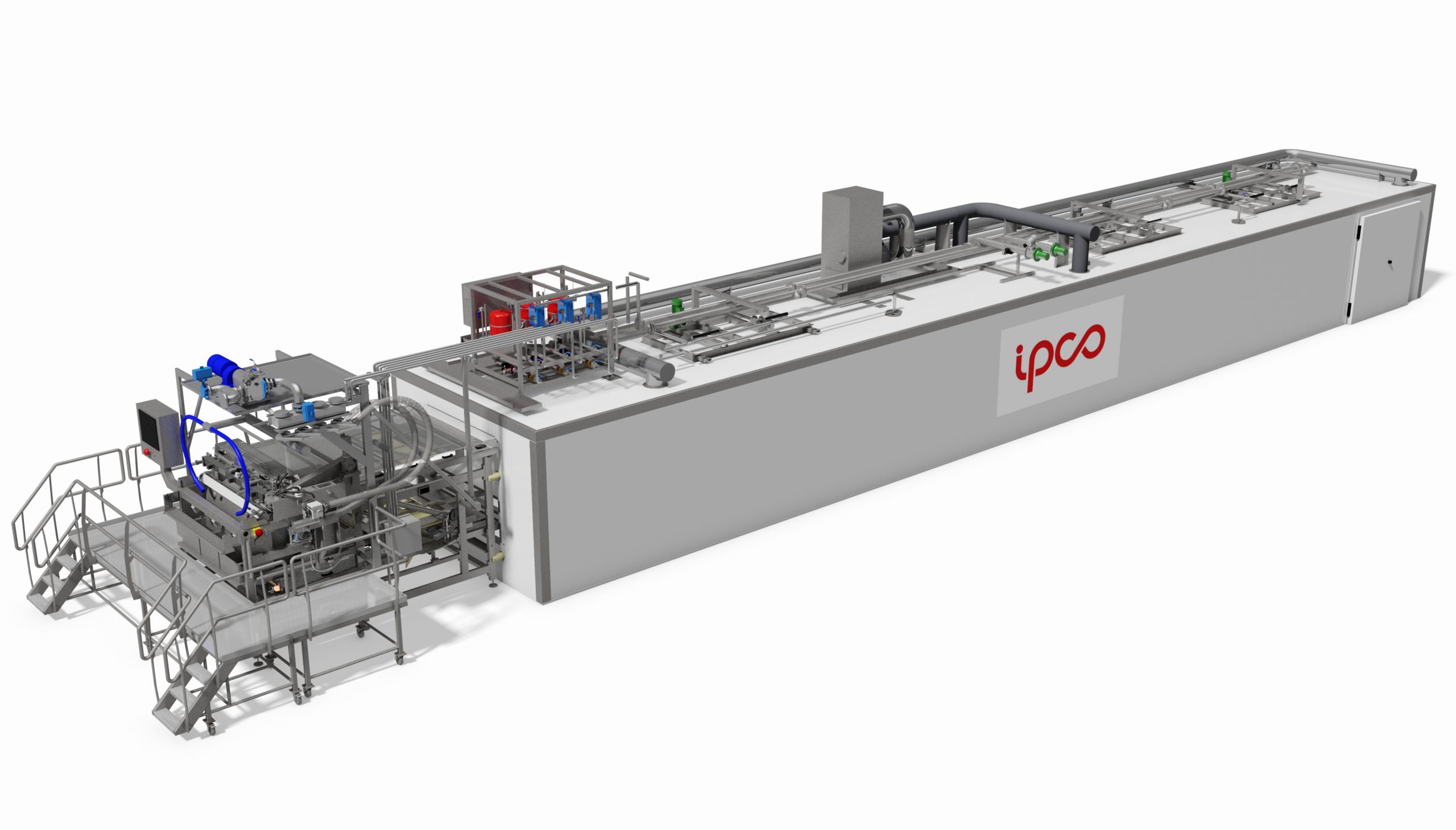

Triple pass cooling

For higher capacity requirements, we have a range of triple pass cooling systems that enable high throughput rates while minimising floorspace requirements. The product is deposited on the first belt and adheres to the underside for the second pass. It is then removed on to a second conveyor for a third pass.

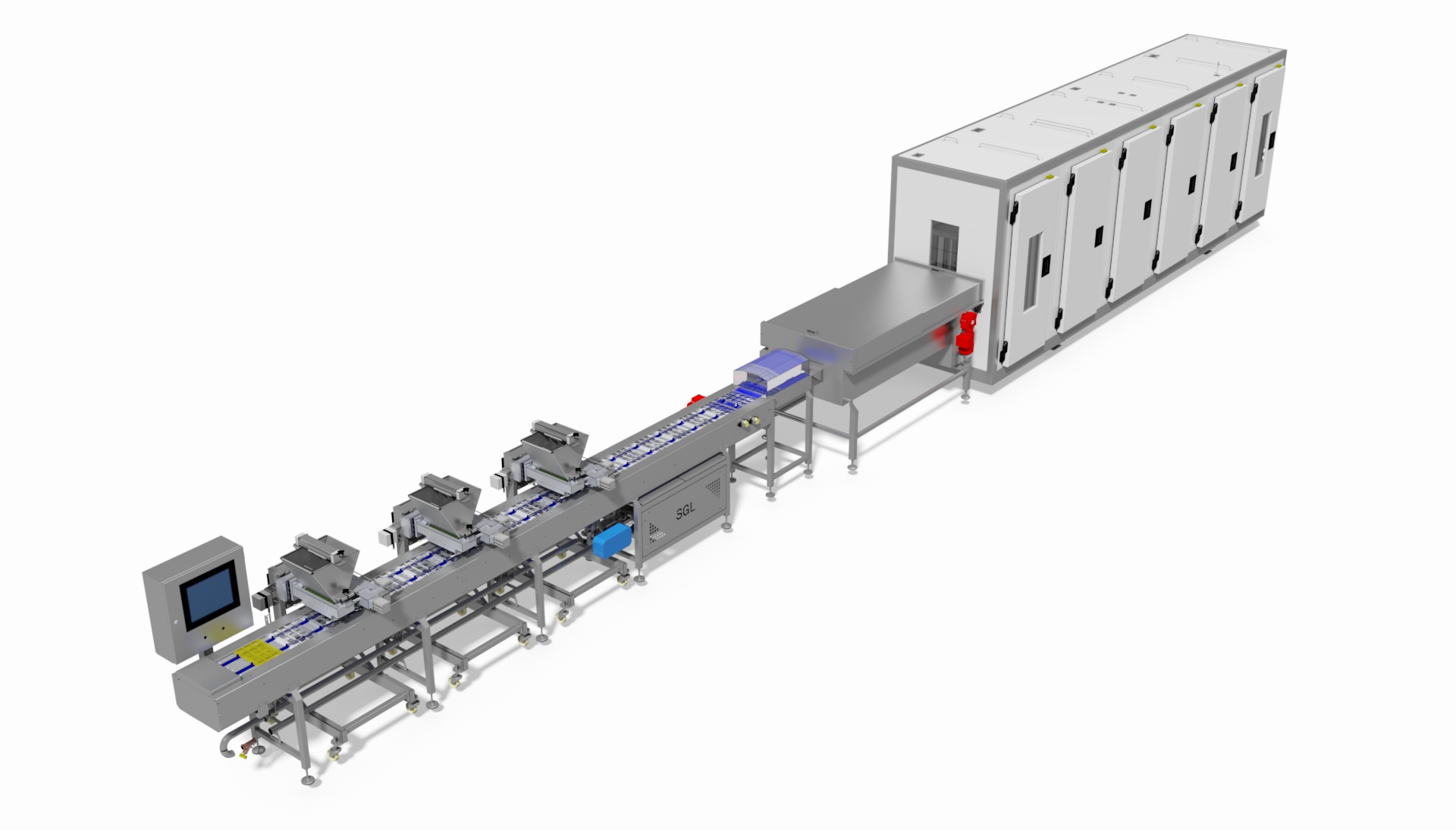

Plastic belts for cost-sensitive, lower capacity production requirements

While steel belts offer unbeatable performance and productivity, if your requirements are for a lower budget solution, we can provide a cost effective solution in the form of a plastic belt-based system.

Plastic belts cannot meet the highest capacity requirements and have a shorter operational life than steel belts, but if you need a low-to-medium capacity system, the lower initial investment cost of a plastic belt system could be an attractive alternative.

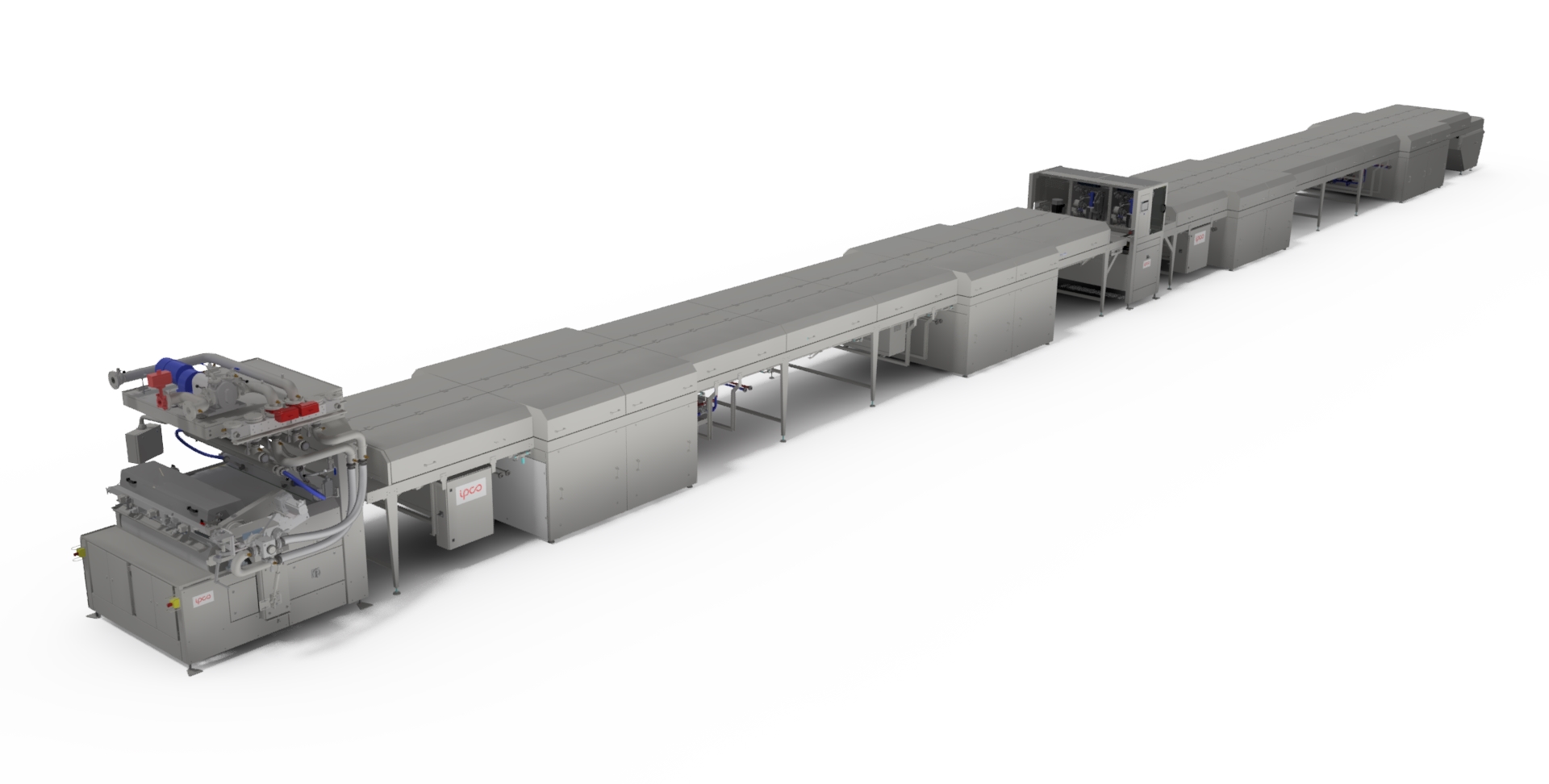

Steel belts and Rotoform pastillation for versatile, high capacity chip production

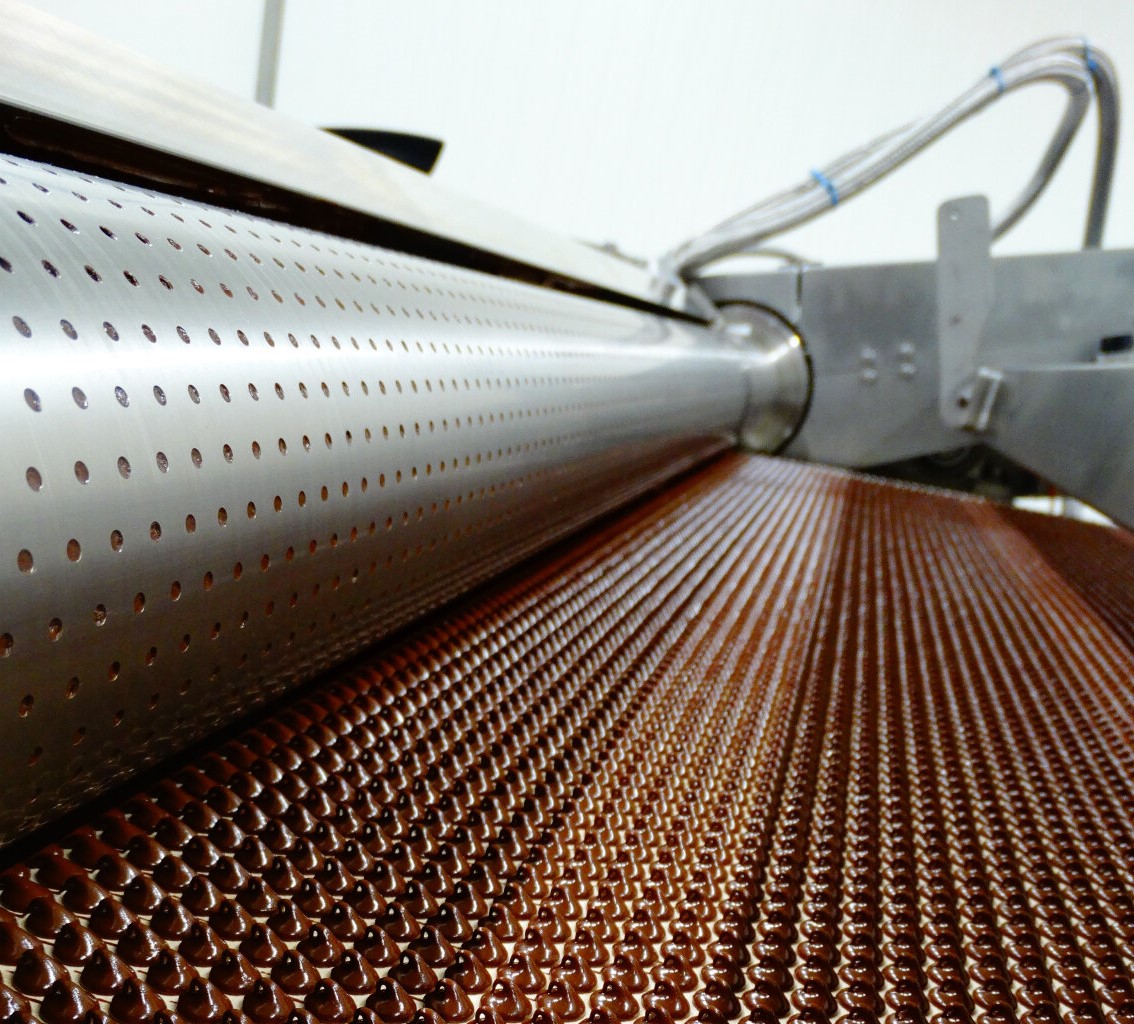

Rotoform

At the heart of all our high capacity solutions is our Rotoform rotary drop depositor, a technology that has proved so successful that more than 2500 installations have been completed worldwide. Rotoform granulation for high quality chips of consistent size and shape

The Rotoform consists of a heated stator and a perforated rotating shell that deposits drops of chocolate onto a continuously running steel belt. Internal baffles and nozzles ensure even pressure to deliver chips that are uniform in shape and size. Chips from 30,000 to 300 pcs/kg can be produced by simply changing the shell.

- Free flowing chips for easy handling, storage and dosing.

- Short cooling time for top quality products.

- Proven technology – 2500+ systems installed in 40+ years.

- Versatile production with easy switching of chip size.

- Global service / spare parts supply.

Steel belts

We are the world’s leading manufacturer of steel belts and have supplying the food industry with conveying and processing solutions for nearly 100 years. This gives us a real insight into what’s important to companies like yours and we’re focused on delivering systems that will meet your business and production objectives.

Market overview

We have the right chocolate processing solution for your business

The global chocolate market is estimated to be worth well in excess of US$100 billion and it continuous to grow. Maximising your share of this market depends on your ability to produce a quality product as cost effectively as possible.

Our high performance chocolate forming/moulding equipment is used by many of the biggest names in chocolate production. Whether you’re looking for a standalone chip moulding system or a complete, end-to-end production solution for industrial ingredients – chips, chunks, drops and blocks – or decorative products – shavings, rolls, pencils, blossoms and more – we have the systems to match.

- Manufacturing steel belts for food processing for nearly 100 years.

- High productivity chocolate forming solutions.

- Global service with local engineering expertise.

- Trusted supplier to world leading chocolate brands.