Prosweets 2024: product launch of our new piston depositor

Hall 10.1 | Stand G080 – Koelnmesse

High productivity chocolate forming with IPCO Rotoform chip production and advanced piston depositor

We are major supplier of chocolate forming/moulding equipment, with systems designed for the production of industrial ingredients – chips, chunks, drops and blocks – and decorative products such as shavings, rolls, pencils, blossoms and many more. A wide range of production components means IPCO can tailor systems to meet different needs, from low cost, rapid deployment start-ups to high capacity multi-layer systems. We will use Prosweets 2024 to highlight the production benefits of two systems from its extensive portfolio

- the IPCO Rotoform HP

- rotary drop depositor and its advanced piston depositor.

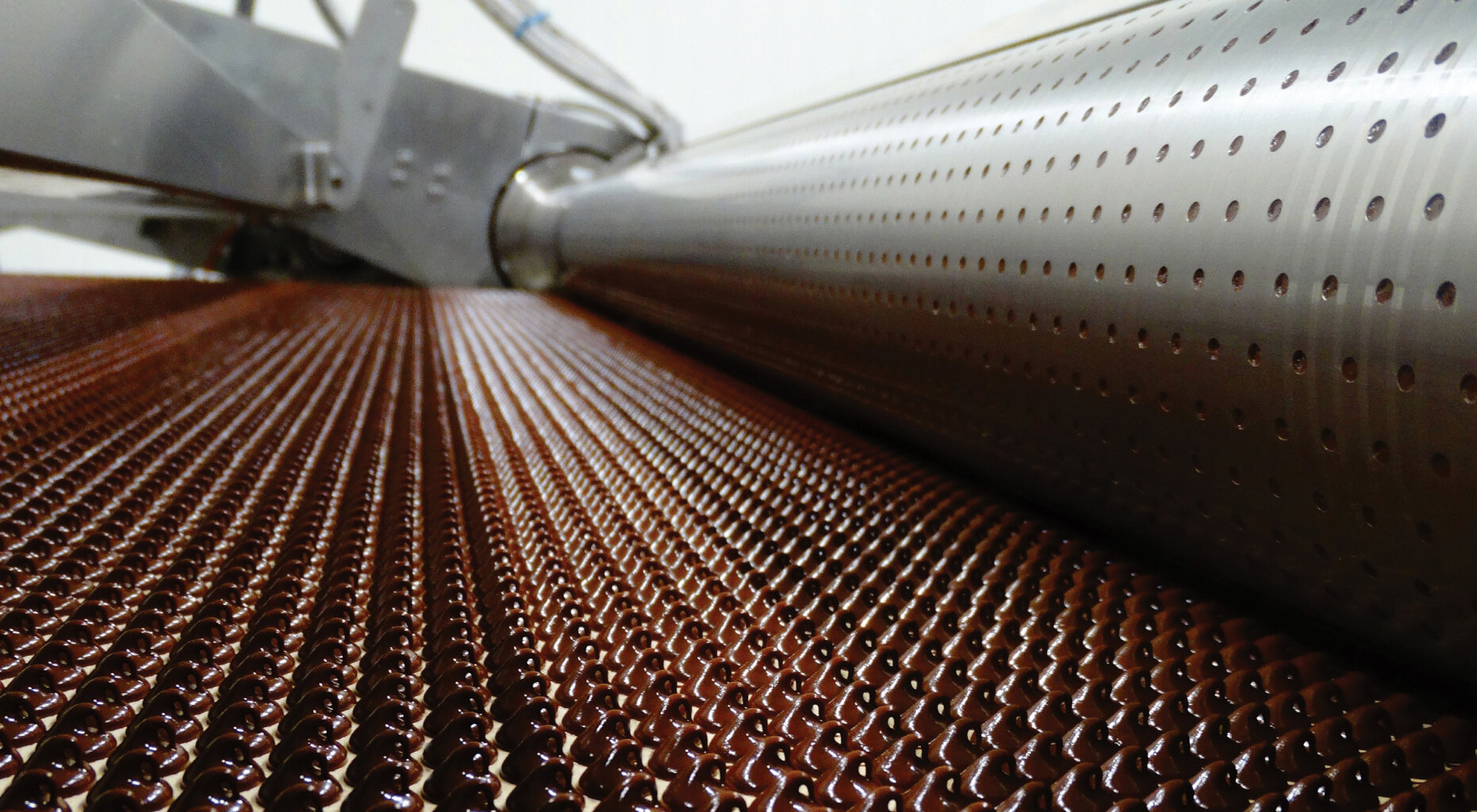

At the heart of all IPCO’s high capacity solutions is the Rotoform rotary drop depositor, and the latest model in this series is the Rotoform HP (High Performance). Specifically designed for chocolate processing, the RF HP has opened the door to new levels of productivity in chocolate chip forming. IPCO will showcase a live demo model of the Rotoform HP dosing unit at ProSweets 2024. A pump delivers the molten chocolate to the Rotoform via heated piping. The Rotoform itself consists of a heated stator – which is supplied with liquid chocolate – and a perforated rotating shell that turns concentrically around the stator to deposit drops of chocolate onto a continuously running steel belt. A system of baffles and internal nozzles provides uniform pressure across the whole belt width, ensuring that chips are of uniform shape and size. The circumferential speed of

the Rotoform is synchronized

with the speed of the belt: drops are therefore deposited without deformation. The heat of the drops is transferred to cooling air blown onto the product and also to the belt itself. A short cooling time means that very little oxygen can penetrate the product. Chips are free flowing for easy handling, storage and dosing. Chips of different sizes – from 30,000 to 300 pcs/kg – can be produced by simply changing the shell.

Piston depositor for large chocolate wafers / chips

The IPCO Piston Depositor is our first solution of this kind and incorporates a number of features designed to take this technology to a new level. This system is a 1500 mm wide depositor that uses a D-motion to deliver chocolate or compound directly onto a moving belt, rather than the belt-to-depositor movement commonly employed on other systems. The speed and height of the depositor is software controlled, ensuring that it travels at exactly the same speed as the belt. This precision control, combined with the D-motion, means a variable deposit can be applied without any distortion of the product, resulting in perfectly circular large – i.e. wide and/or thick – wafer products. The movement of the Piston Depositor is managed by D-motion software and driven by four servo motors, synchronized to the speed of the belt. The depositor travels longitudinally along the belt then completes the D-shape by returning to its starting position. The design of the system means this is achieved using only rotational movements. The fact that no linear bearings are used in the unit means significantly less wear and tear, resulting in lower maintenance requirements.

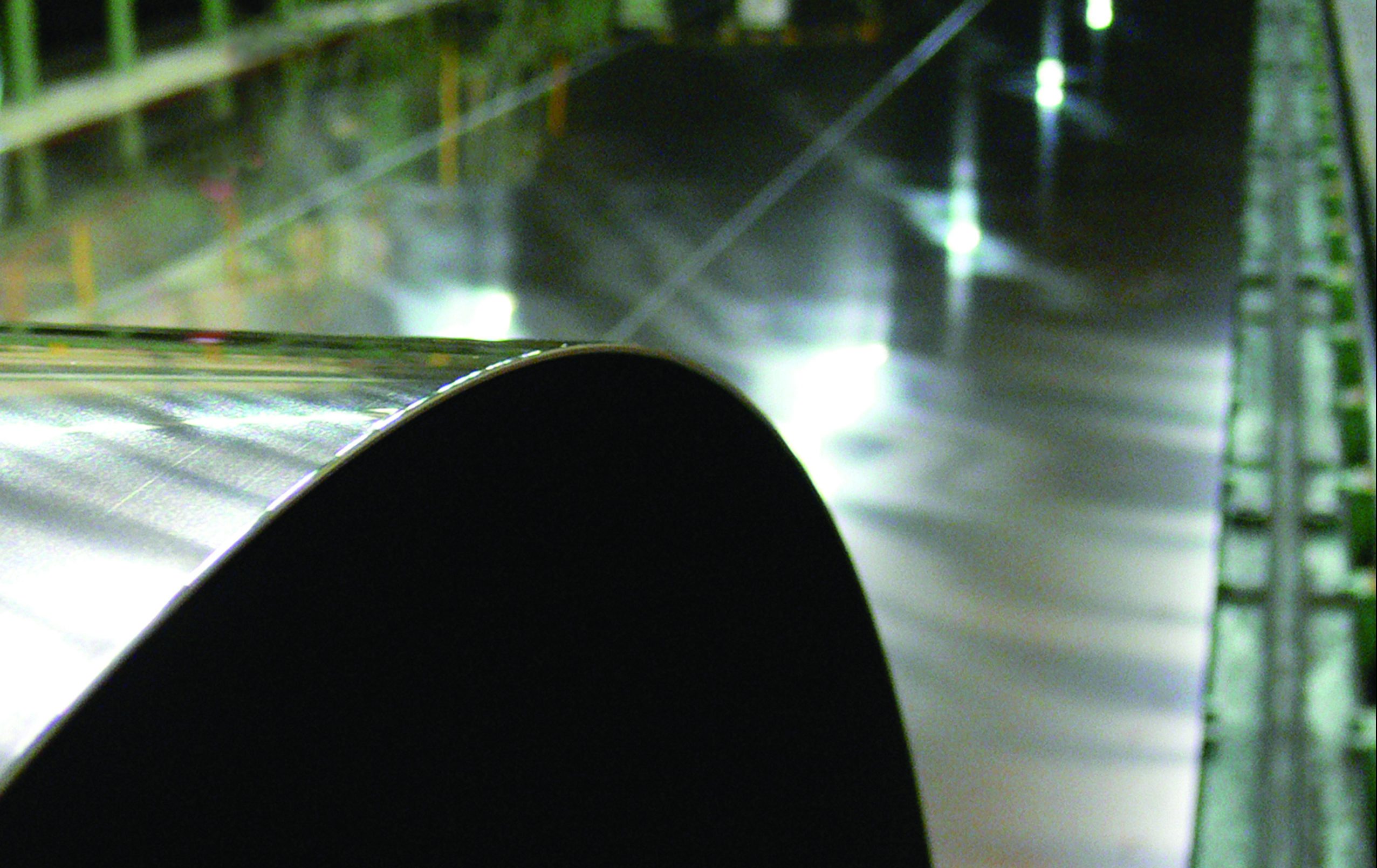

Steel belts for cooling and solidification

IPCO has been supplying steel belts for use in confectionery and chocolate processing for almost 100 years, in applications ranging from simple conveying to continuous processes such as cooling/solidification, conditioning, drop-forming and casting.

Products processed this way include caramel, chocolate, hard melt candy, nougat, nut brittle and more. In each case, the product is applied to the belt as a melt, either through casting or drop depositing, and solidified as it passes through a cooling tunnel. The heat of the melt is transferred to cooling air blown onto the product and also to the belt itself.

We look forward to meeting you in Cologne, January 28-31, 2023, Hall 10.1, Stand G080

Book a meeting with our experts

Mitchell Paquaij

Global Product Manager

Posted: 19 Dec. 2023