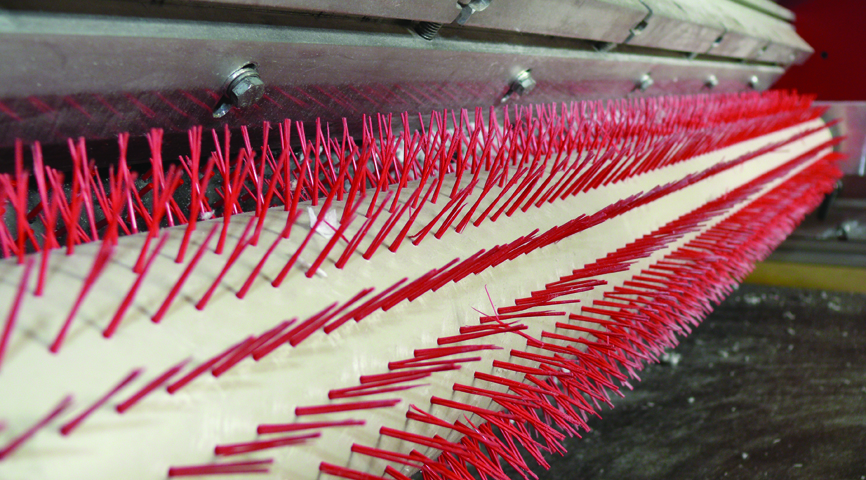

Fiber scattering machine with brush-off roller

Versatile system featuring a brush-off roller for uniform scattering of fibrous materials.

Typical applications for this IPCO precision scattering unit include:

- Automotive industry

- Textile industry

- Recycling industry

- Construction industry

Using either a vacuum or an auger feeding device, the fiber material is conveyed to the scatter coater hopper. In the hopper, the fiber is evenly distributed across the width and kept at a constant level during the scattering process. For bulk materials that tend to bridge due to their flow properties, a specially designed agitator is installed above the metering roller (scattering roller) to prevent bridging.

The fiber material is taken up by the scattering roller and the excess removed by a rigid doctor blade.

The accurately dosed material is then conveyed by the roller to the rotary brush-off system. The counter rotating brush roller cleans the roller and deposits the material onto the substrate or conveyor underneath.

Features

- Specially developed agitator for uniform distribution of fibers in the material hopper

- Doctor blade with adjustable segments

- Optimized scattering roller design to hold the fibers

- Easy adjustment of the distance between brush and scattering roller with position display

- Shell clamping device enables easy change of brush roller – distance to scattering roller remains unchanged

- Scattering machines can be supplied with vertical and horizontal transfer system for easy cleaning and maintenance work

- Standard scattering widths from 500 – 5,200 mm; other widths on request