Our new Compact Belt Tracking system

An evolution in tracking technology

For over 10 years, our Compact Belt Tracking system has been one of the most popular, installed on steel belt conveyors in different industries around the world. Now, we’ve used our extensive experience from the past decade to make extensive improvements, making it easier to use and easier to install.

Here’s what it can do for you…

Continuous controlled tracking logic to increase tracking precision

Experience a leap in tracking precision with the introduction of continuous controlled tracking logic. Our shift from an open-loop control system to a closed-loop design allows for better stability of transient events in the conveyor, ensuring optimal performance and boosting production uptime.

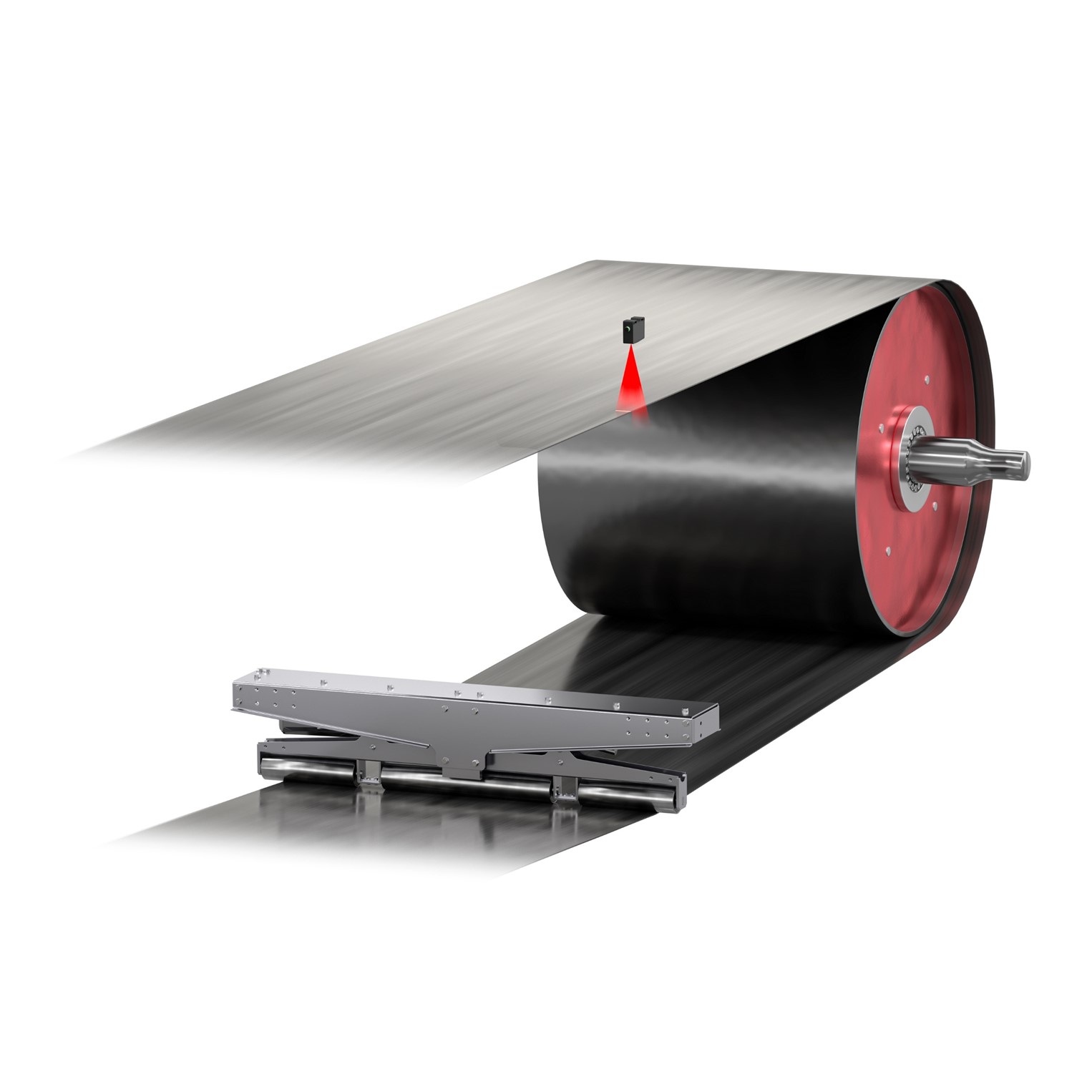

Contact-free belt edge monitoring

A new single optical sensor replaces inductive sensors and measures the belt edge continuously. Since it’s contact-free, there’s much less risk of damaging your belt, plus fewer parts means it’s easier to install and setup.

More robust design

Our advanced technology offers you a simplified system that puts more control in your hands. The redesigned unit is more resistant to wear and reduces play, giving you more precise actuation. Our new custom-made rollers increase precision, reducing noise and vibrations during operations. The result is a conveyor system that will not only last you longer but operates with the utmost reliability.

Easier servicing

Extend your system’s life and increase production up-time by removing and replacing any worn parts without sending the unit for refurbishment. Additionally, we’ve strengthened potential wear points to further increase reliability and give you a longer lifecycle.

CBT 2G Datasheet

IPCO CBT 2G animation