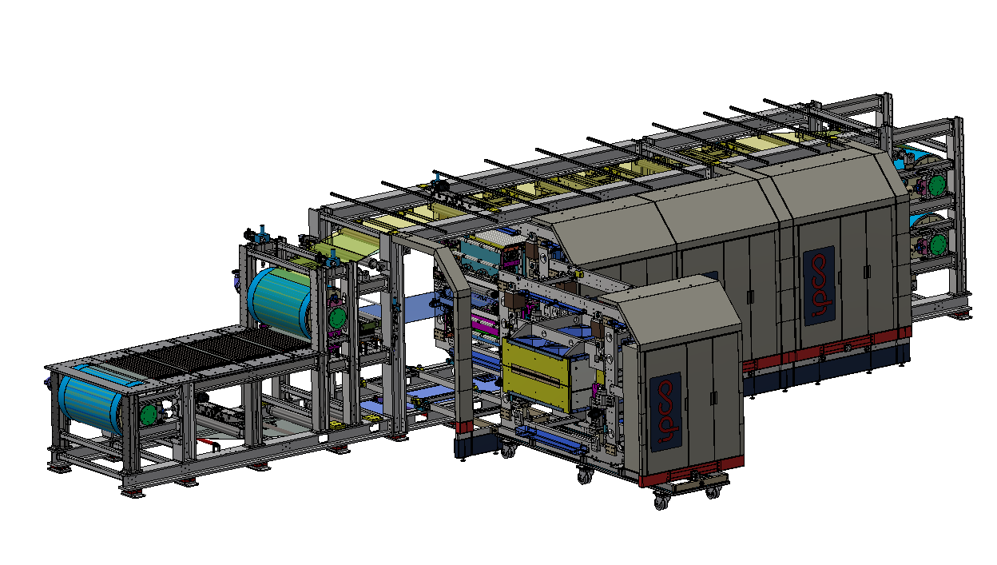

We are upgrading our performance center in Goeppingen to even better serve our customers: A new IPCO modular steel belt test press is currently being installed and will be available for product tests by the end of March.

The new test press is 16,5 m long, has a belt width of 1200 mm and is much closer to a production line than the previous test press was, providing reliable process data for the design of a commercial machine.

The new system is designed according to the proven modular concept, i.e. four press modules can be interchanged and combined as required, providing maximum flexibility. By increasing the temperature range to 400°C and the pressure range to 20 bar and higher, we have the possibility to process high performance composite materials and are well prepared to meet the current market demands.

The test line can be operated in combination with up to two scattering units. Taking into account our leading position in scattering technology, we are following the demand of many of our customers who initially run tests on one of our PTFE belt lines and would like to compare the performance with a steel belt press.

The machine will be equipped with the latest measurement and control technology for controlling the process parameters such as speed, temperature, pressure and thickness calibration to ensure the best possible product quality.

Read more about our productivity center in Göppingen.