Bio-based composites

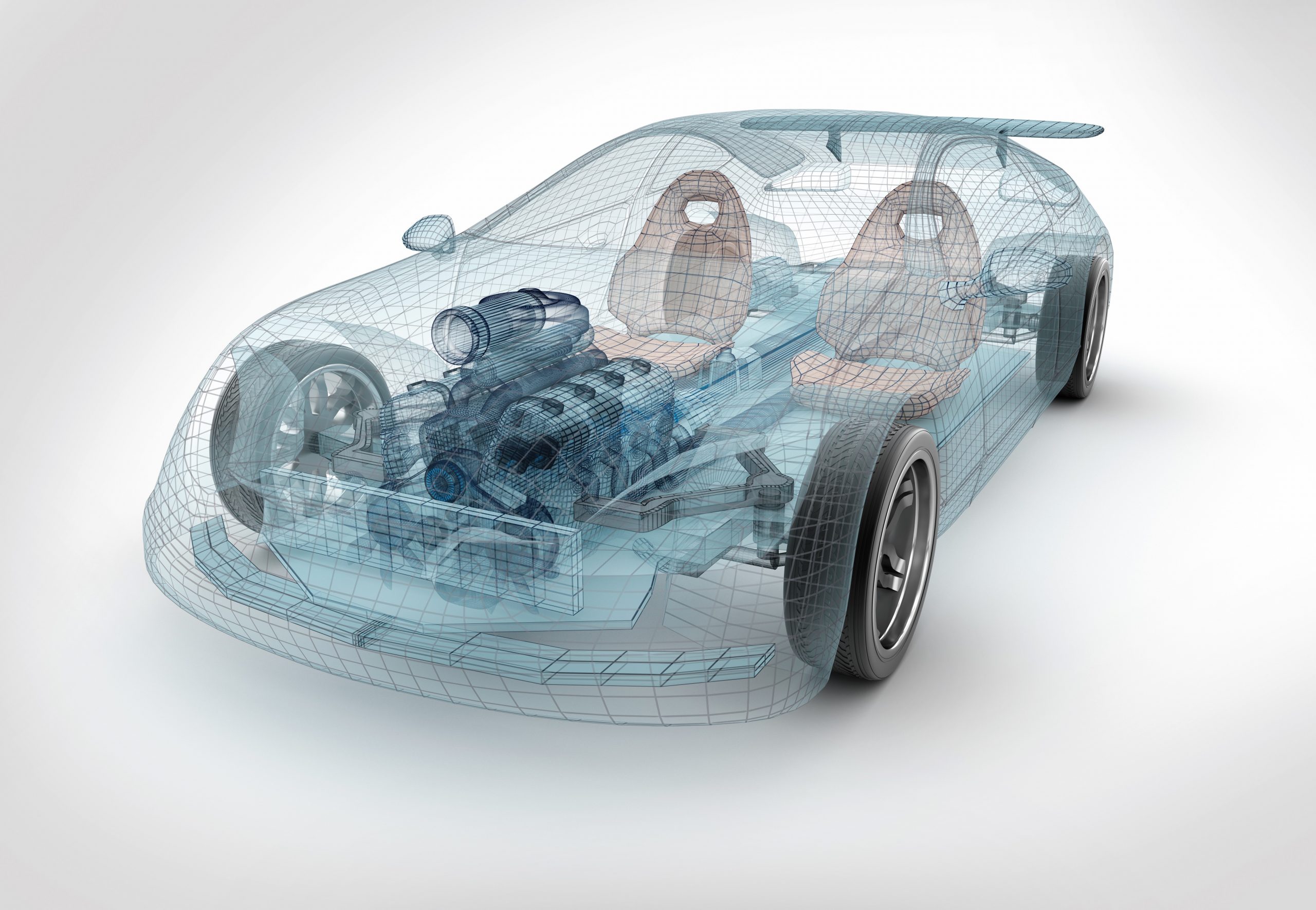

In the race to decarbonize transport, bio-based composites can help you transition to low-carbon transport or develop new e-mobility.

Sustainable solutions

Whether you’re navigating the electric vehicle space or commercial transport, IPCO’s products and expertise support you in manufacturing the sustainable, lightweight, high-strength, high-quality components you need.

Our technologies, including double belt presses and scattering systems, help you create high-performance bio-based composites for a more sustainable future for transportation.

New wave in high-performance composites

Our advances in manufacturing techniques means you can shift away from thermoset composites to more recyclable thermoplastics or switch to natural fibers, bio-based and recycled materials.

IPCO double belt presses and precision scattering systems are already integral to the industrial-scale production of composite materials in various sectors, including building, interior design, transportation, aerospace, and automotive. And now these proven technologies are ushering in the materials of tomorrow.

High-performance composite materials

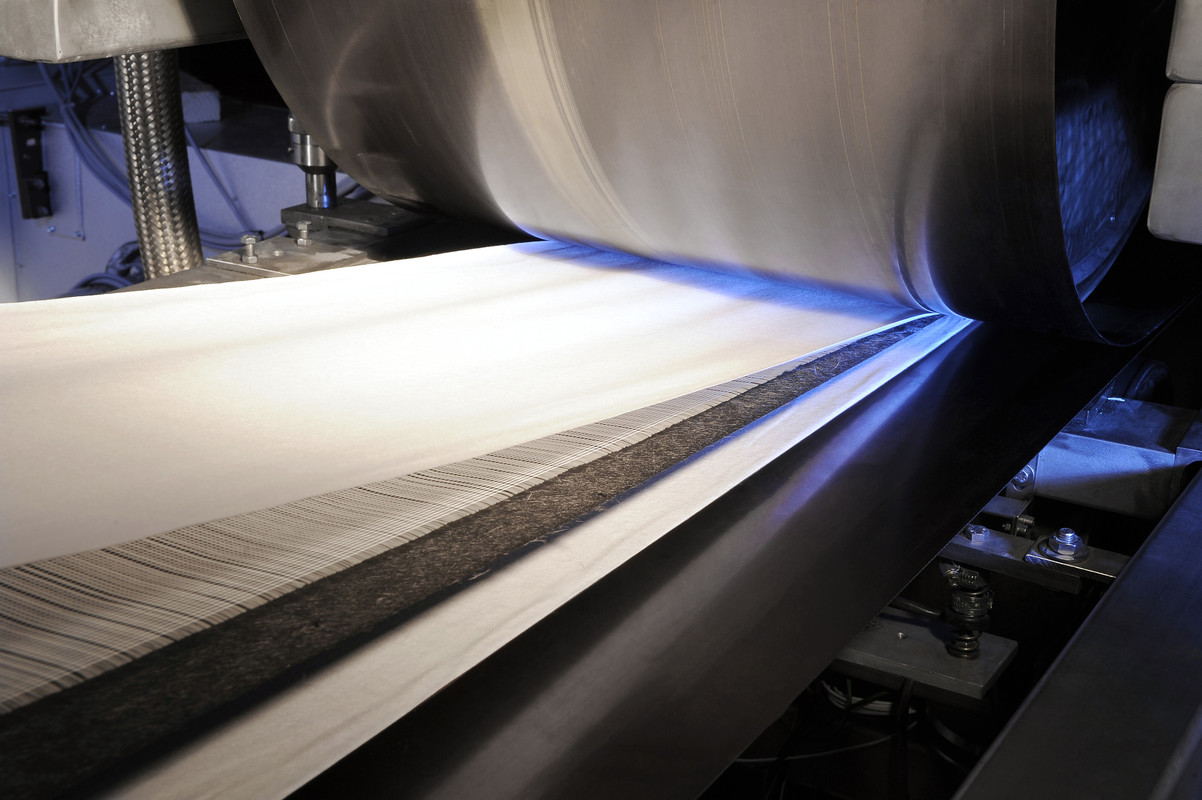

IPCO is the world’s leading manufacturer of double belt presses and scattering systems for the production of advanced composites. Our flagship ThermoPress range is modular in design, enabling you to incorporate controlled heating, reaction consolidation and calibration, cooling and tempering processes into a single highly-efficient production system.

Customized solutions for all types of composites

IPCO is the world’s only double belt press manufacturer offering you systems based on PTFE belts, steel belts and a combination of both. Our ThermalPress TB series uses PTFE belts and his design for consolidating two or more materials. The steel belt-based ThermoPress SB range enables heating and cooling under pressure and is used for high quality thermoset and thermoplastic composites. And our patented ThermoPress CB system is a combo belt solution that delivers the best of both worlds. Each is available to you with a choice of pressure modules enabling the supply of customized solutions for all types of composite material.

Precision scattering technologies

IPCO is also the world leader in precision scattering technologies. Our ScatterPro range is the most extensive on the market with a choice of oscillating and rotating brush-off systems to handle powder, granules, fibers, chips, flakes, another flowable bulk materials.

This versatile technology allows you to produce a wide range of high-quality composite materials. We have recently introduced the benefits of ScatterPro to the world of industrial 3D manufacturing. ScatterPro systems can be operated as standalone units or combined with ThermoPress systems in fully integrated end-to-end production lines. ThermoPress and ScatterPro are market-leading technologies that offer you efficient production solutions for high performance composites.

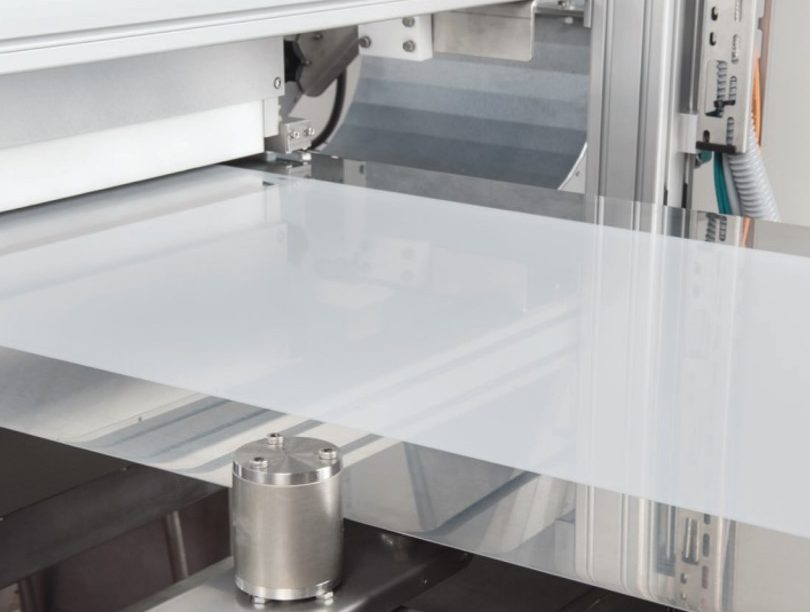

Flat sheets for efficient processing

To make it easier for you to handle, load and transport, our technology can produce composites as flat sheets, minimizing waste and maximizing efficiency.

This also makes it easier for you to process the composite straight off, without extra steps to unroll and cut to size.

Bio-based composites in numbers

Double belt presses

100+

In operation worldwide, contributing to the evolution of transportation materials.

Scattering units

300+

In operation worldwide, contributing to the evolution of transportation materials.

Delivery time

1-14

months. Ensuring swift adaptation of sustainable practices.