IPCO shot peening technology has proved an effective solution for flattening deformed steel belts used in WBP presses, cooling lines and bake ovens for many years. The shot peening process blasts steel balls at high pressure across the width of a belt as it turns around the terminal drum. This equalises stresses on both sides of the belt to remove concave deformations and eliminate associated issues such as tracking problems, high stresses and risk of accidental damage among others.

Premium quality belt for premium quality end product

The process is suitable for most steel belt applications including cooling lines and bake ovens, but is most widely used to restore press belts in the WBP industry where the condition of the belt has a direct impact on the quality of end product. Successful production of board products requires the correct application of controlled pressure and heat across the full width of the end product; any deformation of the belt can have an adverse impact on this process.

The shot peener balances the stresses in a belt, restoring it to a perfectly flat condition and ensuring:

• Premium quality end product.

• Prolonged belt life.

• Reduced likelihood of unexpected repairs.

• Reduced scrap.

• More efficient production.

Advanced design for even greater performance

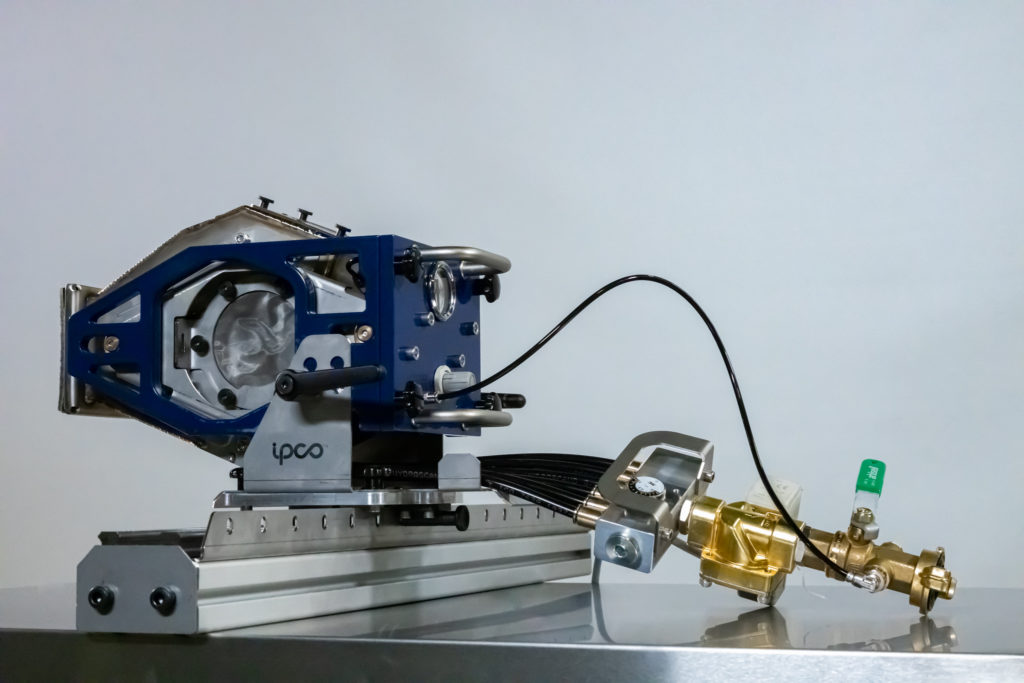

The next generation Shotpeener Pro incorporates a number of technical advances that have significantly increased this performance, enabling us to restore belts that might previously have been beyond repair.• Increased blasting effect.

• 30% greater flattening capacity.

• Faster results.• Streamlined process with less cleaning.

• Easier, safer operation.

Fast and effective restoration of deformed belts

The Shotpeener Pro is a portable unit that can be installed on site to repair deformed steel belts in situ. In the case of WBP presses, this repair work can be carried out without interrupting production.This offers major advantages over the traditional repair technique of ‘belt turning’, which requires the belt to be cut, removed, turned, remounted and rejoined, a process that could take many days.Once mounted in place, the Shotpeener Pro can repair a deformed belt in between 3-18 effective hours, depending on belt dimensions, thickness and degree of deformation.

For more information on the IPCO Shotpeener Pro and to discuss the service options available, please contact your local IPCO office.