Customer Case NFW

IPCO’s double-belt press solution and what it means for NFW

In 2021, IPCO secured a contract to supply a Double-Belt Combi Press for NFW, the leading producer of alternative leather for the fashion and automotive industries. NFW’s ground-breaking product, MIRUM®, is entirely biobased, petrochemical-free and has been developed in line with the circular economy model. As consumer demand for more sustainable products grows exponentially, IPCO’s state-of-the-art Combi Press means NFW is able to scale production to meet the surging demand for alternative leathers.

IPCO’s double-belt presses are the only platform capable of producing alternative leathers such as MIRUM at the capacity now required to meet demand.

IPCO’s unique Double-Belt Combi Press solution with steel and PTFE belts, includes up- and downstream equipment and precision scattering systems, meaning one solution for multiple production stages. It is modular, and designed to enable different processes within one continuous system. This multi-stage approach incorporates controlled polymerization, curing, and cooling, and enables the development of a multitude of highly efficient, environmentally friendly processing solutions. It is a horizontal processing sequence, which prevents material tensions developing within the product and guarantees successful results.

Core advantages of IPCO’s double-belt presses include:

- ability to manufacture material at scale on a continuous roll rather than piece by piece

- efficiency benefits of one continuous process

- flexibility to process different types of material and/or product on the same system with a high level of process control

- constant high-quality output

- designed to minimize waste and energy consumption

- high degree of automation.

IPCO’s solution for NFW

IPCO supplied a customised Combi Press to NFW in Peoria, IL. The Combi Press uses proven double-belt pressing technology, pressing between two steel belts for strength while also utilizing a PTFE belt for optimal release properties and to avoid waste of carrier foil. The machine, which measures 30 meters (over 32 yards) and weighs in at 420 metric tonnes (over 460 US tons), is the result of decades of experience and know-how from IPCO’s German press solutions team and has been customized to meet NSW’s requirements. The technology was patented by IPCO in 1969 and has since been applied and developed in over 800 installations for the production of wood-fiber-based products.

Thanks to the Combi Press, which went live in May 2023, NFW can transition production from a static to a continuous output to match the ever-growing demand.

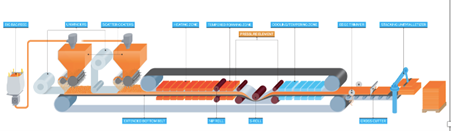

Example of double-belt press processing

The illustration below shows how the backing raw material of vinyl flooring is produced within a double-belt press in a process similar to that used for MIRUM.

- Dry blend or granules are fed into the system using a scatter coater on the bottom belt.

- The backing raw material is pressed together.

- The material is heated, then formed and lastly cooled, while constantly pressurized.

- Cutting and finishing.