This is the main headline

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Duis at tincidunt justo.

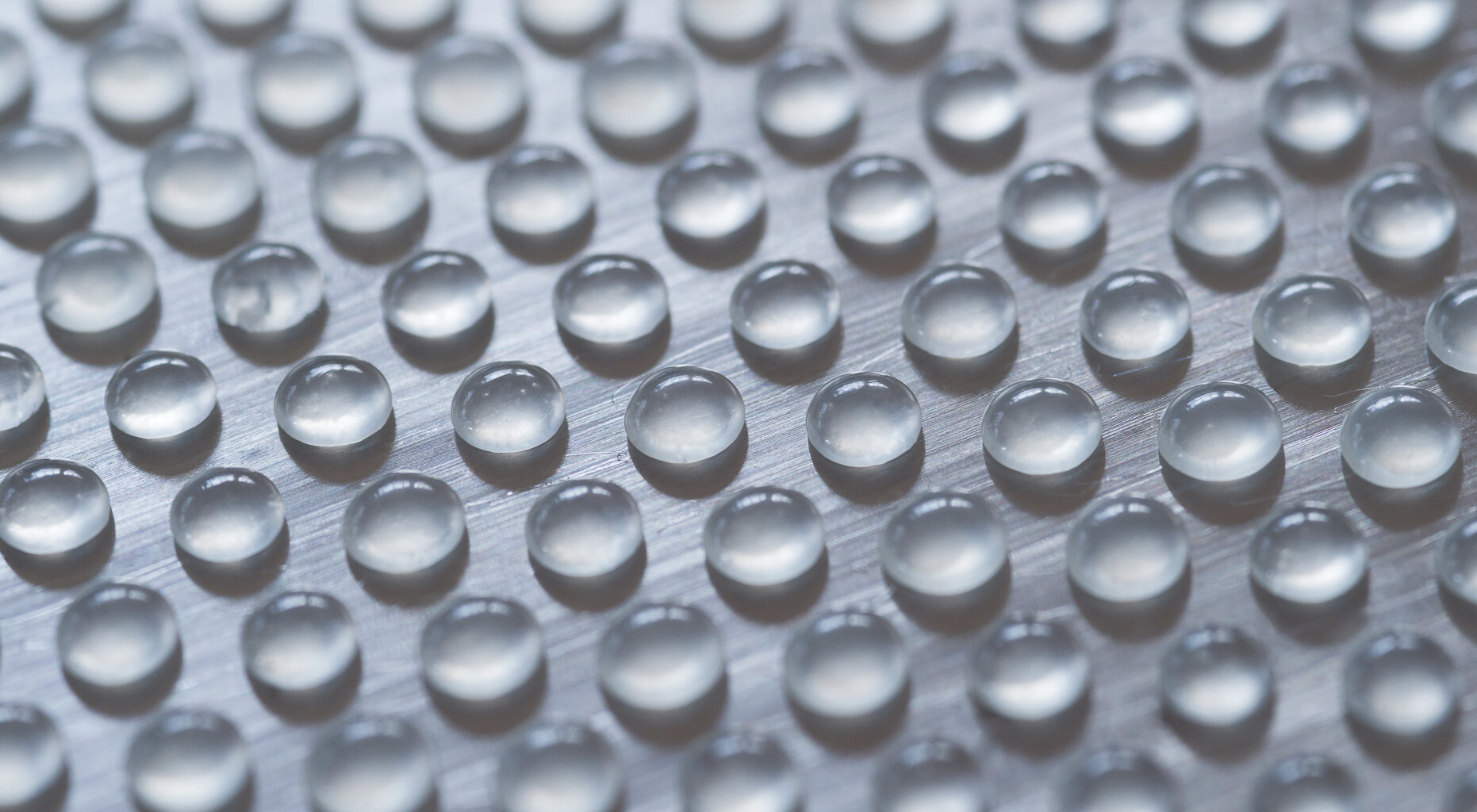

Rotoform 4G FD granulation system

Our Rotoform 4G FD granulation system is specifically designed for the pastillation of a wide range of food products and ideally suited for the pastillation of chocolate. Offering all the benfits of the basic Rotoform granulation system – reliability, product quality and easy of operation – Rotoform FD granulator has been developed to maintain the highest standards of hygiene.

This is a H3 subheading

Our Rotoform 4G FD granulation system is specifically designed for the pastillation of a wide range of food products and ideally suited for the pastillation of chocolate.

This is a H4 subheading that you use under an H3

Our Rotoform 4G FD granulation system is specifically designed for the pastillation of a wide range of food products and ideally suited for the pastillation of chocolate. Our Rotoform 4G FD granulation system is specifically designed for the pastillation of a wide range of food products and ideally suited for the pastillation of chocolate.

Steel belts for food applications

IPCO steel belts are used for processing chocolate and other confectionery products, with applications ranging from simple conveying to continuous processes such as cooling/solidification, conditioning, drop-forming, casting, freezing, baking and finishing.

- IPCO steel belts are used for processing chocolate and other confectionery products,

- with applications ranging from simple conveying to continuous processes such as cooling/solidification, conditioning, drop-forming, casting, freezing, baking and finishing.

- The key benefits of a stainless steel conveyor belt are outstanding

The key benefits of a stainless steel conveyor belt are outstanding thermal properties, excellent return on investment and unparalleled cleanability for maximum hygiene.

IPCO steel belts are used for processing chocolate and other confectionery products, with applications ranging from simple conveying to continuous processes such as cooling/solidification, conditioning, drop-forming, casting, freezing, baking and finishing.

The key benefits of a stainless steel conveyor belt are outstanding thermal properties, excellent return on investment and unparalleled cleanability for maximum hygiene.

IPCO steel belts are used for processing chocolate and other confectionery products, with applications ranging from simple conveying to continuous processes such as cooling/solidification, conditioning, drop-forming, casting, freezing, baking and finishing.

Facts about Ipco

Just a few numbers that are vital to our existence

Productivity center

9

Lorem ipsum dolor sit amet, consectetur adipiscing elit derfer.

Dolor sit amet, consectetur

Read more

Total ipco employees

600

Lorem ipsum dolor sit amet, consectetur adipiscing elit derfer. Dolor sit amet, consectetur

Find out more

The belt runs at a speed synchronized to that of the depositor, ensuring that the hemispherical drops are of a consistent size and shape

Namn Namnsson, VD Bolaget AB