The ProCool system automates the adjustment of liquid sulphur feeding temperature, free of emissions, for optimum performance and highest quality requirements of pastillation.

Lowering the feeding temperature of the liquid sulphur ensures the highest capacity output, best quality pastilles and lowest dust formation.

Liquid sulphur typically exits the CLAUS process at around 135-140 °C, which can cause a loss of quality and capacity in the downstream solidification process, and can also result in unwanted dust generation.

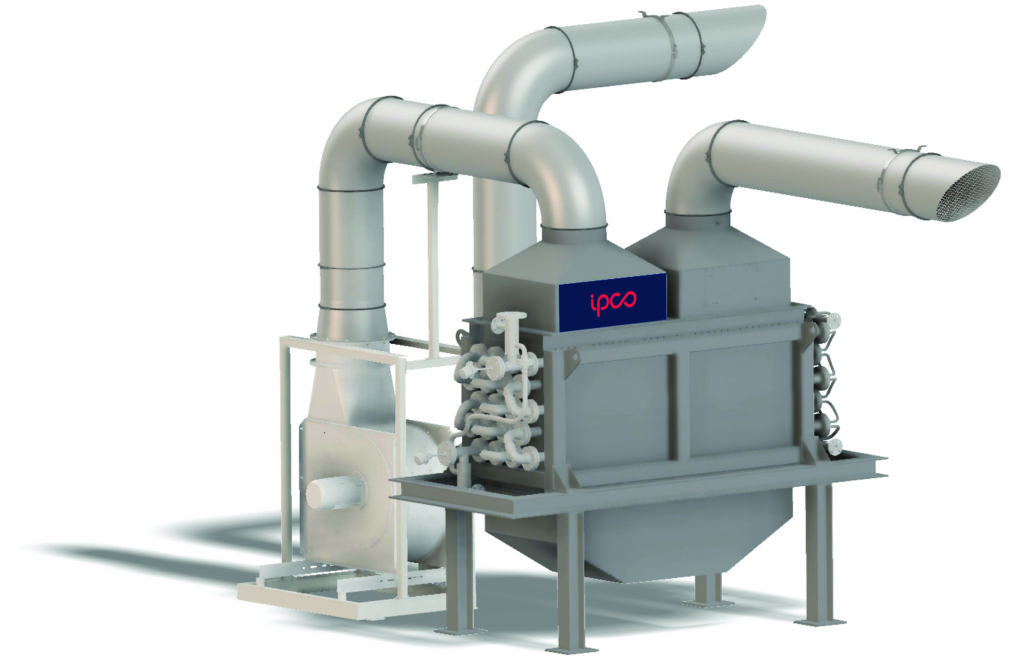

IPCO’s patented ProCool system is designed to lower the temperature of liquid sulphur to the optimal level of 125-128 °C in preparation for the granulation / pastillation process.

This ensures that product quality and throughput rates are optimised, excessive dust formation is avoided and the solidified sulphur meets the SUDIC specifications.

Features and benefits compared to previous pre-conditioning system:

- Simple process.

- Free of emissions.

- Fully automated.

- Less equipment involved.

- Less rotating equipment.

- Low maintenance requirement.

- Low spare parts costs.

- Low utility consumption.

- Modular design to suit all capacities.

- Compact design.

- Heat recovery possible.